Breakthrough in the synthetic replication of composite-material structures found in Mother of pearl

A team of researchers from Konstanz and Hefei (China) synthetically replicate the mineralisation process that takes place in natural nacre

Biomaterials play a crucial role in the development of future high-performance materials. A naturally occurring example of such biomaterial, the mollusk shell, guides chemical replication processes in laboratories. Due to its complex chemical construction, however, these processes are not easy to replicate synthetically. Chemists at the University of Konstanz, in cooperation with the University of Science and Technology of China (Hefei, China), are now the first to synthetically reproduce the structural configuration of natural mother of pearl or “nacre”. To develop the multiscale structures in nacre, the chemists rely on calcium carbonate, chitin and silk fibroin gel as original components. Their production process creates the same structural composition and the nearly identical characteristics of the naturally occurring biomineral. The research results were published by Helmut Cölfen, professor of Physical Chemistry at the University of Konstanz, and his colleagues on 18 August, 2016 in the online edition of the the prestigious journal Science.

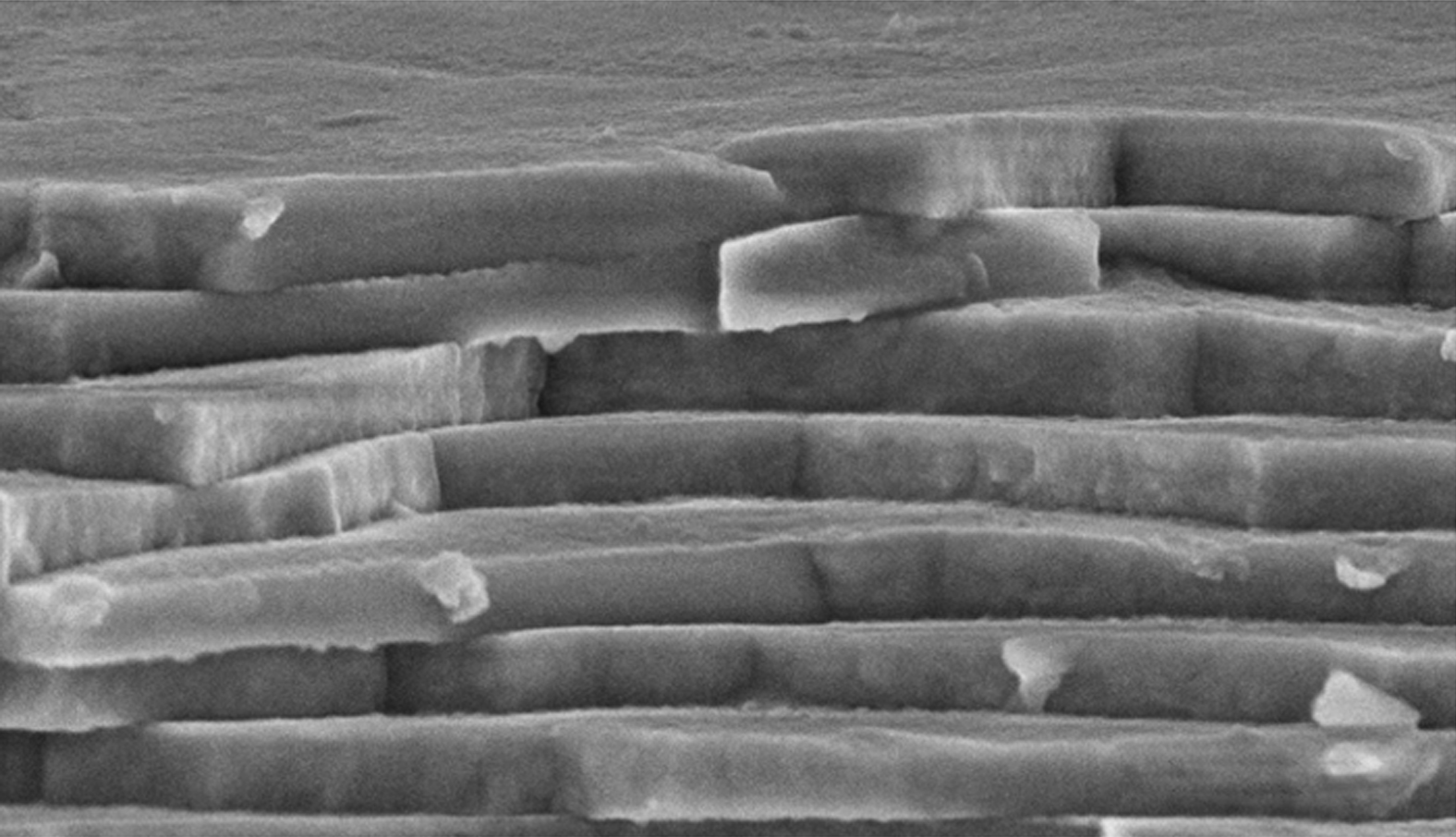

The key to developing nacre, which is 3,000 times more fracture resistant than the calcium carbonate it primarily consists of (95%), lies in the replication of the hierarchically arranged structure comprised of its particle-level components. Previous efforts to produce synthetic nacre involved attempts at replicating its layered structure. Unfortunately, the natural mineralization process, which many mollusks such as oysters or snails use for the production of nacre, could not be imitated. The researchers around Helmut Cölfen developed a new procedure where the natural components of nacre were used in consecutive layering and mineralization processes. They were able to simultaneously control the mineral structure in the nano- and micrometer range during a so-called ‘mesoscopic approach’. In this way, the chemists were able to create a biomineral that is almost identical to the naturally occurring nacre. The material is hard, fracture-resistant and is based on – in contrast to the results of previous production attempts – the insoluble structure of chitin, just like in the natural nacre.

“The advantage of this approach is that we can substitute higher-grade components for the brittle calcium carbonate base material during the production process. This means that including mechanically superior materials instead of calcium carbonate in our manufacturing process will allow us to produce high-performance materials in the future – all based on the design of the mollusk shell and our bioinspired research”, explains Helmut Cölfen. His synthetic production process has one significant advantage over nature: It is faster. The developmental process of naturally occurring nacre takes months, if not years. Helmut Cölfen’s process takes two weeks.

Helmut Cölfen is professor of physical chemistry at the University of Konstanz since 2010. His research focus is on crystallization and biomineralization processes. He has carried out pioneering research in the area of non-classical crystallization. Thompson Reuters counts him among the world’s 100 most influential chemists between 2000 and 2010. Helmut Cölfen is spokesperson for the Collaborative Research Centre 1214 ‘Anisotropic Particles as Building Blocks: Tailoring Shape, Interactions and Structures“, which carries out research on the directional properties of particles and their superstructures.

Original publication:

Synthetic nacre by predesigned matrix-directed mineralization

H. Cölfen, L.-B. Mao et al., Science 10.1126/science.aaf8991 (2016).